About Our Products

About our Ventilation and Filtration Systems

SHELTER VENTILIATION

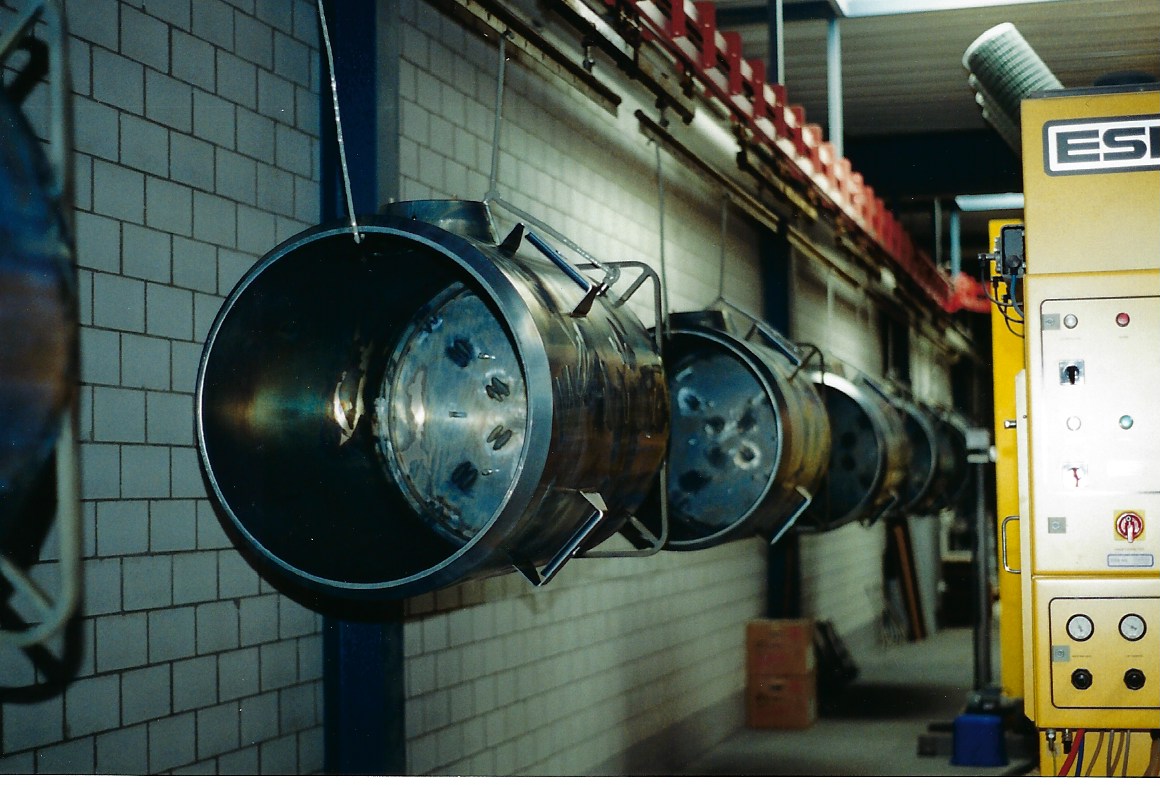

These proven shelter components are found in high quality shelters worldwide and are recognized as THE premier supplier of shelter technology. Andair AG produces their products in their own factory in Andelfingen, Switzerland following the rigid specifications established by the Swiss Federal Office of Civil Defense and, the Swiss Defense Technology and Procurement Agency.

Ventilation systems are available for shelters of all sizes for occupancy from 7 to 2,000 persons. Of course, multiple units can be installed in a single shelter facility to meet any capacity requirement (some hardened shelters in Switzerland can handle more than twenty thousand people). All Andair AG air handling units are capable of both electric and manual operation. Test samples are subjected to 16 g’s in all six directions to assure ruggedness; paint, metals and rubber hoses are tested against all war gasses; and the HEPA and charcoal filters are tested with a highly technical process to assure the proper volumes and densities needed to filter and absorb all known war gasses.

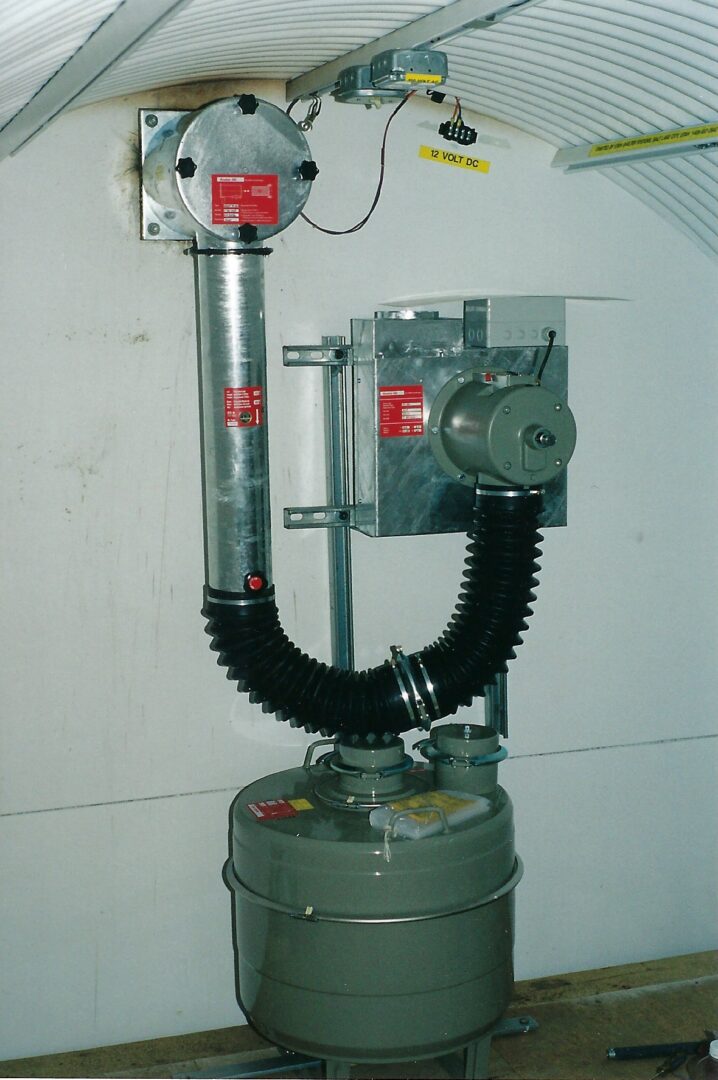

Our most popular model, the VA-150, comes standard with a 1 bar (15 psi) explosion protection valve/pre-filter assembly, air pump, exhaust over-pressure explosion protection valve, hoses, clamps, and GF150 Gas Filter. In peacetime, the system bypasses the gas filter and delivers 177 cubic feet per minute (cfm). With the gas filter connected, the recommended air rate is 88 cfm to allow for complete scrubbing of the outside air.

A shelter with a ventilation system that is totally dependent on electricity leaves its owners vulnerable. Shelter power supplies can fail. Sometimes batteries die when they have unexpectedly reached the end of their service life, or lights have inadvertently been left on with the charger unplugged and have drained the battery. For whatever reason, manual operation of all life-critical systems essential for shelter operations are required to be manually operable to assure readiness.

During a blast, hot gasses under extreme pressures can enter through the air vents. In order to attenuate this shock wave, a blast valve (also known as an explosion protection valve) must be placed into all air pipes, vents and other penetrations to the shelter.

Blast valves instantly shut off the flow of air when a shock wave enters the air vent. This not only protects the other components of the ventilation system from damage but prevents injury to shelter occupants.

Some shelter manufacturers do not wish to go to the trouble and expense of installing blast valves into their air vents and address the problem instead by using a very undersized (less than 2-inches in diameter) air pipe.

Small diameter air pipes cause a ‘choking’ effect and they hope that only a limited amount of blast will enter the shelter through this undersized pipe…but this also means that only a limited amount of fresh air will enter the shelter as well.

This small, open-ended air pipe also allows for continual loss of air pressure and for exchange of air from the outside world. It is mandatory that continual positive pressure be assumed for the proper protection from war gases.

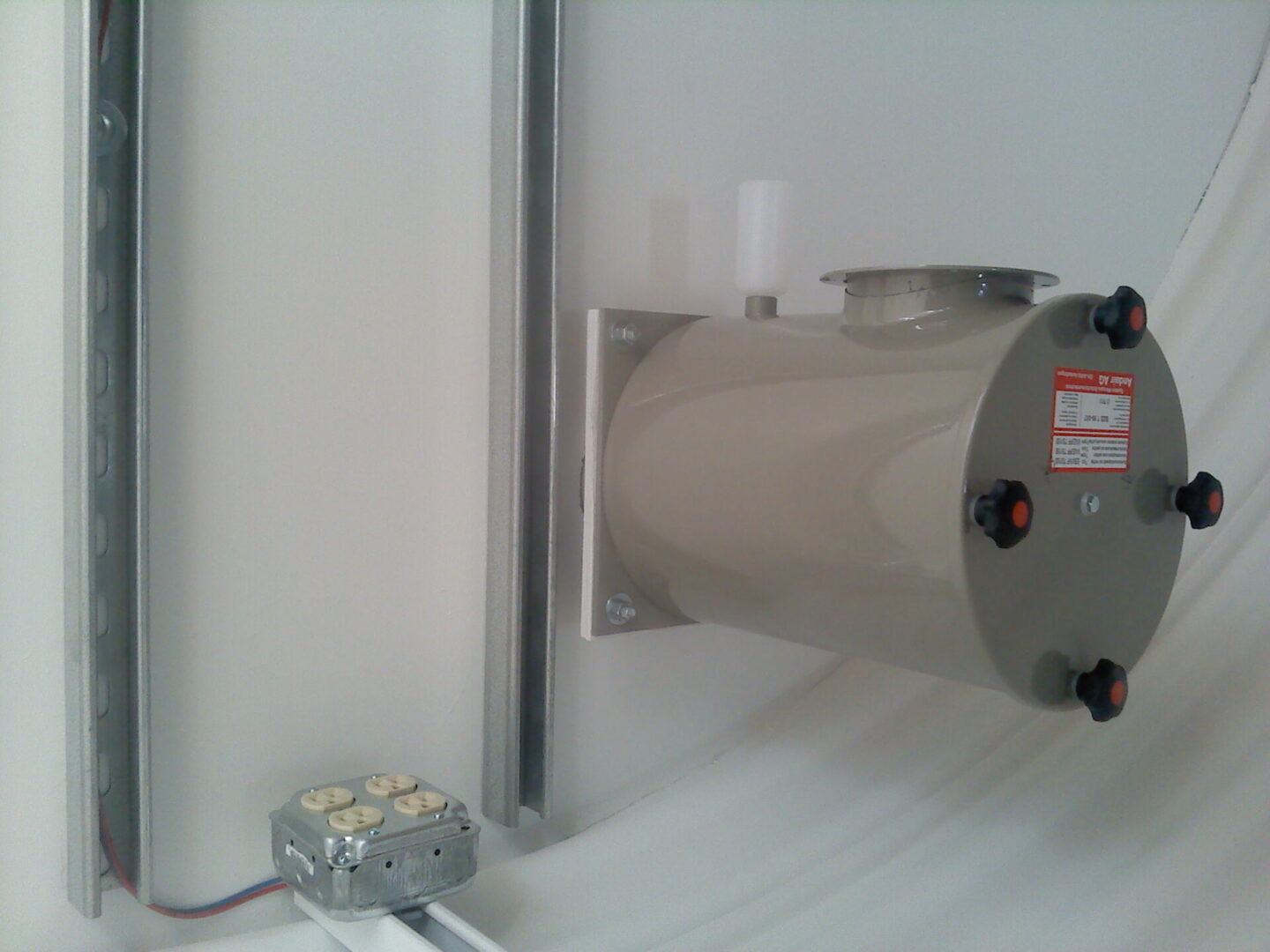

All ventilation pipes should be constructed from 5 or 6-inch diameter schedule 40 steel pipe, which will not burn, crack, or easily distort. This pipe size assures a generous flow of air. All of our systems are be fitted with blast valves that have been tested and certified by a legitimate government laboratory, thereby assuring our customer adequate protection from these serious life-threatening effects.

Used as pressure resistant closures of air inlets and outlets for shelters for civil defense and other exposed buildings. LUWA Blast Valves

How often and for how long the air handling unit should be operated depends on the size of the shelter, the number of occupants, and the capacity of the unit.

Assuming a family of six in a 3700 cubic foot shelter, they may wish to operate the air system for an hour every six hours or so to freshen the shelter atmosphere. This schedule is not very close to the level of desperation, but it does maintain good morale and comfort for shelter occupants.

In order to maintain acceptable air quality in a shelter housing twenty to thirty occupants, the ventilator should be run for twenty minutes and then rested for twenty minutes. Fifty occupants is considered the absolute limit with a single VA-150 and would require continuous operation to support life.

This assumes a steel or concrete shelter with un-insulated walls that will absorb body heat and keep temperatures under control. The combination of insulated walls, lots of occupants, and inadequate ventilation will cause temperatures to soar to intolerable levels in a short period of time.

With this many people in a shelter, there will be a larger number of volunteers to operate the system (imagine the consequences of losing power with an electricity-dependant air handling unit under these conditions). The “ventilation officer” will also have the job of listening to the radio (perhaps on headphones) to stay informed about an ongoing situation. For this reason, we suggest that you position the radios near the ventilation unit.

ANDIAIR specializes in concrete filled shelter closures. Exterior Civil Defense shelter doors should fit against the wall facing the potential blast. A proper blast door should never fit into the frame of the shelter opening. During blast or earth movement, shelter openings can bend and could block the entrance.

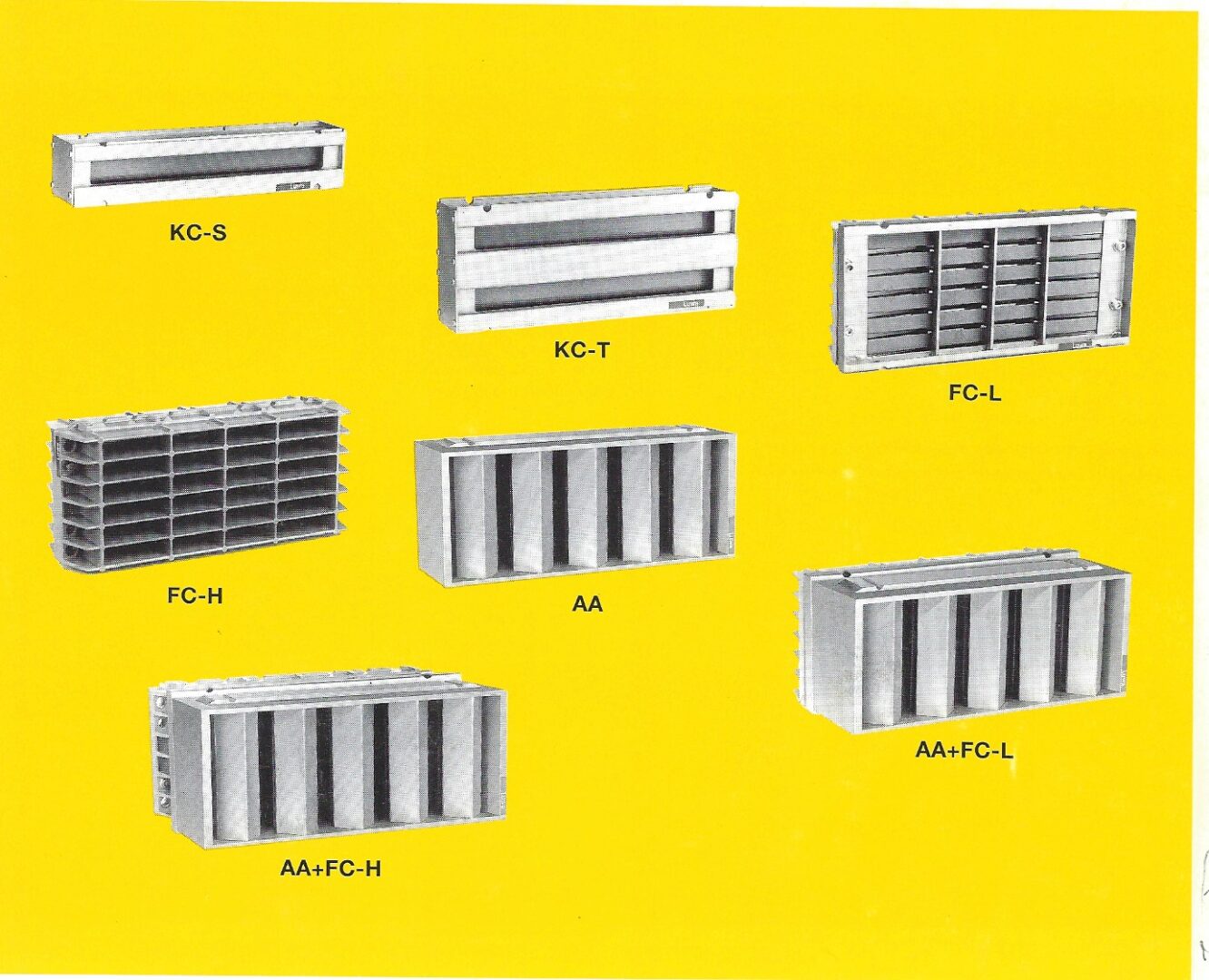

Andair AG Gas Filters protect against the following war gases:

Gas filters do NOT protect against carbon monoxide and dioxide. A separate filter is available for scrubbing carbon dioxide from the shelter atmosphere during a period of time when outside air is not suitable. This could occur if burning debris is too close to the air intake vent.

A hardened NBC shelter should have the capability to shut down the outside source of air for a period of 6 hours, for sealed shelter operation. During the first hours of a nuclear attack, smoke, carbon monoxide, and radiation particles could overcome the ventilation and filtration systems. It is assumed, after this 6-hour period, that carbon monoxide levels from the smoke outside would have dissipated. However, carbon dioxide (CO2), which is an internal threat, builds very quickly in occupied sealed areas. A concentration of CO2 over 3% in the sheltered area is unacceptable.

Each person will produce about .67 cubic feet/hr. of CO2. Plan your shelter space to accommodate each person with enough room to breathe safely and comfortably for that 6-hour period. Each person needs 88 cubic feet of free air volume to shut down for 6 hours. Design your shelter with double that volume, to accommodate for furniture, food, water and other supplies. A 10 ft. x 32 ft. shelter will accommodate 14 people and supplies in a ‘shut down’ mode for 6 hours.

It would appear from this example that the shelter could be rather small. However, it should be noted that the air space for breathing must be totally empty space. You must, therefore, add about 5 cubic feet for the mass of each person. You must also add additional space for food, water, supplies and furniture. A good rule of thumb would be to multiple the required air space by a factor of 2.5; and for the example above, the volume of the shelter should increase to 2100 cubic feet.

If there is a need to accommodate more people than your shut down mode can accommodate, you should purchase our carbon monoxide scrubber, or purchase compressed air tanks. Remember, however, it is not so much a matter of depleted oxygen, as it is a matter of too much carbon dioxide. Do not store oxygen tanks inside your shelter. They pose too much of a danger.